If you hear your HVAC expert talk of superheat and subcool you might wonder what they are talking about.

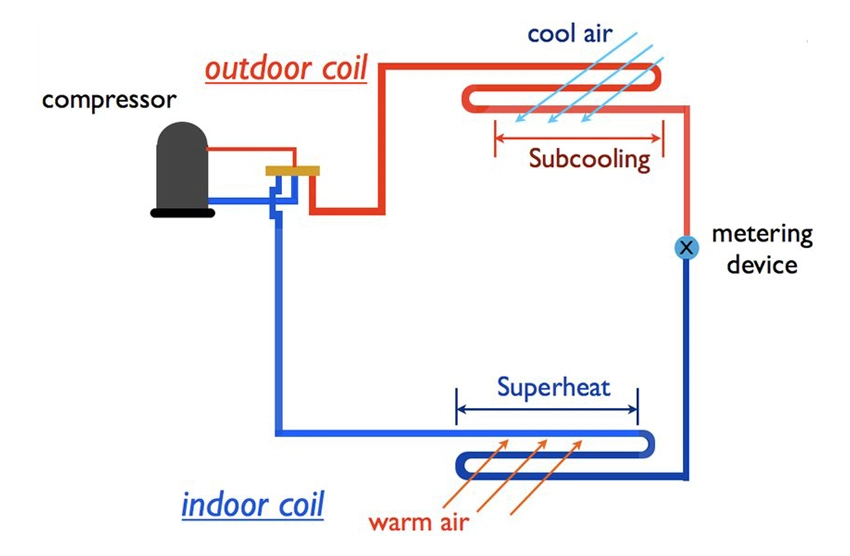

Superheat is the temperature of refrigerant vapor above its boiling point, which makes sure the refrigerant remains in vapor form as it exits the evaporator coil. Superheat, in simple words, means how much hotter the refrigerant gas is than its boiling point at a given pressure. This shows us if the refrigerant fully changed from liquid to gas in the evaporator. Only gas should go to the compressor – liquid can break it.

Subcooling, on the other hand, is the temperature of the refrigerant liquid below its boiling point, which guarantees that the refrigerant stays in liquid form as it leaves the condenser.

Superheat and subcooling in HVAC are crucial concepts because they ensure your HVAC system works efficiently and effectively. There is a fine balance when the refrigerant flows through the system as it should and provides optimal cooling and heating without wasted energy.

As HVAC experts here at Pure Eco Inc., we keep a close eye on the refrigerant of your HVAC system. We are happy to provide you with a free consultation- 18778707998 to answer all your questions.

Key Takeaways:

- Superheat is the heat added to the refrigerant gas after it boils in the evaporator. It ensures only vapor reaches the compressor, preventing damage.

- Subcooling is the cooling of refrigerant liquid below its boiling point in the condenser. It ensures the refrigerant is fully liquid before entering the expansion valve for efficient cooling.

- Ideal superheat range is 10–20°F. Too high = poor cooling. Too low = compressor risk.

- Measuring superheat and subcooling helps spot system problems, save energy, and improve performance.

- Tools needed: pressure gauge, thermometer, and PT chart or digital calculator.

- Common issues: incorrect refrigerant charge, airflow problems, or faulty valves.

What is Superheat in HVAC?

Superheat in HVAC refers to the amount of heat of the refrigerant vapor that exceeds its boiling point. It’s the extra heat added to the vapor so that it remains in a gaseous state as it exits the evaporator coil. This crucial deviation from saturation temperature ensures that the refrigerant can absorb heat efficiently. That’s how the cooling process within the HVAC system works.

Superheat is important in the refrigeration cycle because it prevents the formation of unwanted liquid refrigerant at the evaporator’s outlet. This phenomenon guarantees that only superheated vapor, which is essential for efficient heat transfer, enters the compressor.

By maintaining the refrigerant in a gaseous state, superheat optimizes the cooling and dehumidifying functions of the HVAC system and contributes to its overall performance and energy efficiency.

Get Free Estimate!

Request Your Home Comfort Estimate

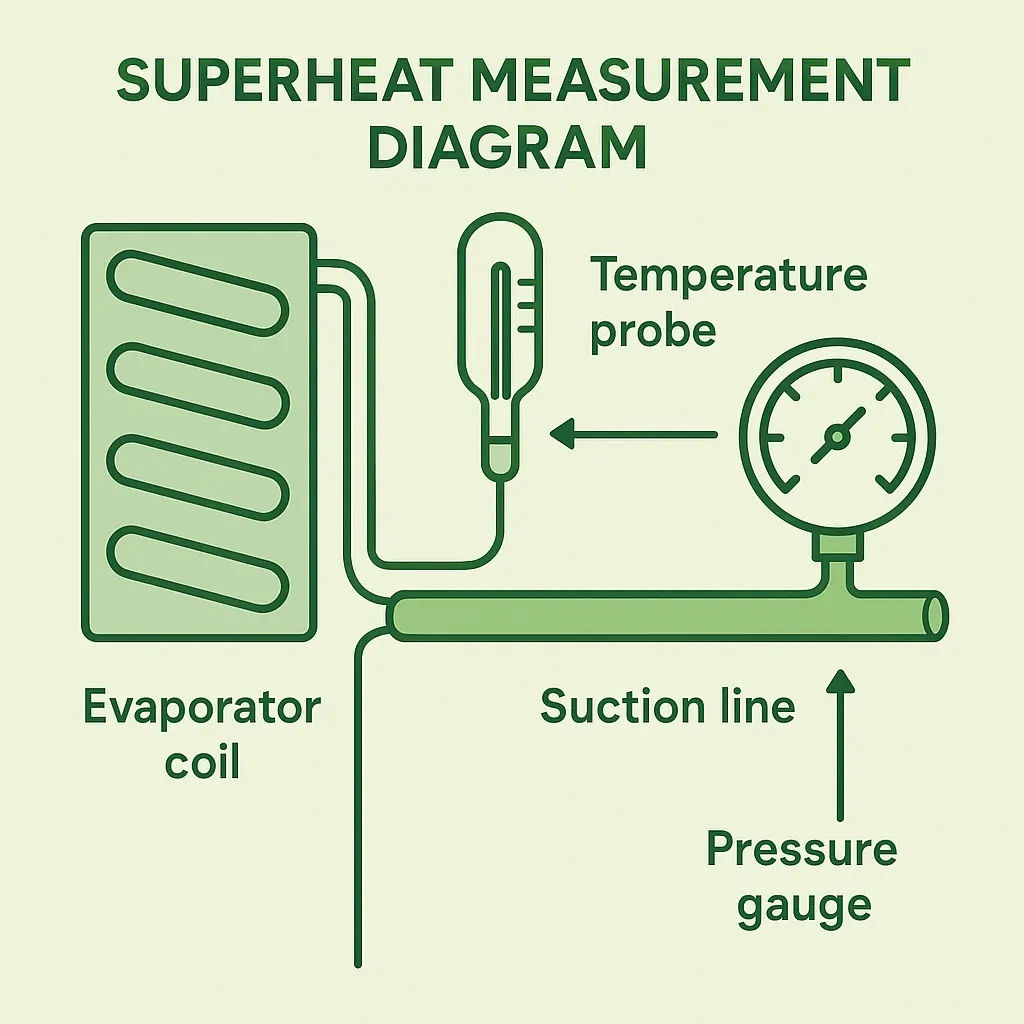

Determining Superheat – The Measurement Process

As HVAC experts, we calculate superheat precisely with specific tools designed for HVAC professionals. The most common instrument is the suction pressure gauge which determines the temperature and pressure of the refrigerant. Additionally, a digital thermometer and a pressure-temperature (P-T) chart come in handy in the process.

Step-by-Step Measurement Process

Follow the steps below to accurately measure superheat and maintain the optimal performance of your HVAC system to ensure that your home keeps a comfortable indoor temperature.

- Let the HVAC system operate first for 15 to 20 minutes to ensure precision in your measurements.

- Before starting, ensure that your HVAC system is safe to work on. Shut off the power and allow the system to stabilize.

- Identify the suction line and the evaporator coil. The suction line is where you’ll measure the temperature, and the evaporator coil is where you’ll measure the pressure.

- Attach the pressure gauge to the low-pressure side (suction line) and the digital thermometer to the refrigerant line. Make sure they are securely connected.

- Record the pressure reading from the pressure gauge and cross-reference it with the P-T chart to find the corresponding saturation temperature.

- Use the digital thermometer to measure the actual temperature of the suction line. This temperature should be above the saturation temperature obtained in the previous step.

- The superheat is determined by subtracting the saturation temperature from the actual temperature. The result is the superheat value in degrees Fahrenheit.

How to Measure, Adjust, and Monitor Superheat Accurately

Superheat is the difference between the actual temperature of the refrigerant gas leaving the evaporator and the saturation temperature, which is the point when the refrigerant changes from liquid to gas at a certain pressure. Measuring superheat correctly helps your HVAC system work better, use less energy, and avoid damage to the compressor.

At Pure Eco Inc., our HVAC experts know that accurate superheat measurement and adjustment can make your system last longer and lower your energy bills. Below, we explain the simple steps to measure superheat and the tools we use.

You will need a pressure gauge or manifold gauge set, a thermometer or clamp-on temperature probe, and a superheat calculator or digital gauge with a built-in calculator.

How to Measure Superheat

- Measure Suction Line Temperature. Place the temperature probe on the suction line near the evaporator. Write down the temperature. This is T1.

- Measure Suction Pressure. Connect the pressure gauge to the low-pressure port of the system. Write down the pressure. This is P1.

- Find Saturation Temperature. Use a PT chart or superheat calculator to change the pressure (P1) into its matching saturation temperature (T2).

- Calculate Superheat. Now, subtract the saturation temperature from the suction line temperature: Superheat = T1 – T2

Here is one more example calculation.

- Suction line temperature (T1): 58°F

- Suction pressure (P1): 68 psi (for R-22 refrigerant)

- Saturation temperature (T2): 40°F (from PT chart)

- Superheat = 58°F – 40°F = 18°F

Our HVAC technician at Pure Eco Inc. recommends a superheat of 10–20°F for most home systems, depending on the manufacturer’s instructions and system conditions.

Superheat Measurement Diagram

This diagram shows the 2 key steps for measuring superheat correctly. First, place the temperature probe on the suction line near the evaporator coil to measure the actual temperature of the refrigerant vapor leaving the coil. Second, connect the pressure gauge to the same suction line to read the refrigerant pressure.

Using both readings, you can calculate the superheat by converting the pressure reading into a saturation temperature (using a pressure-temperature chart), then subtracting it from the actual temperature. Accurate superheat measurement can prevent system damage, improve cooling, and save energy.

How to Adjust Superheat

If your system has a TXV (Thermostatic Expansion Valve), you can adjust superheat by slowly turning the valve’s stem. If your system has a fixed orifice, you may need to adjust the refrigerant charge instead.

“Be careful when adjusting superheat. Small changes can affect how well your system cools and can even damage the compressor. We always use digital gauges with real-time data to get it right.” – Beni, Senior HVAC Technician, Pure Eco Inc.

Today, smart thermostats and digital gauges can track superheat in real-time and send alerts. Some systems use smart sensors (IoT devices) to send this data straight to a technician’s phone or tablet, so problems can be fixed quickly.

Need professional HVAC maintenance? Contact Pure Eco Inc. for expert service in Los Angeles

Recommended Superheat Range

In most residential HVAC systems, the ideal superheat range is between 10°F and 20°F. This range helps the system cool your home efficiently while keeping the compressor safe.

If the superheat is lower than 10°F, it may mean there is too much refrigerant or not enough airflow. In this case, liquid refrigerant could reach the compressor, which can cause damage.

If superheat is higher than 20°F, it could mean the system has too little refrigerant or a problem with the expansion valve. This causes poor cooling performance and higher energy use.

Pure Eco Inc. Expert Tip:

“Always follow the manufacturer’s guidelines, but 10–20°F is a good target for most home systems. In some cases, 12–15°F gives the best balance between comfort and efficiency.” – Beni, Senior HVAC Technician, Pure Eco Inc.

When superheat falls outside the proper range, you may see:

- Poor cooling: High superheat means early vaporization, leaving part of the coil unused.

- Frost on evaporator outlet: Low superheat often means liquid refrigerant exiting the evaporator.

- High compressor discharge pressure: Overheating and reduced compressor life

Our technicians use digital tools to check superheat accurately and adjust it if needed, helping your HVAC system work safely and save energy.

What is Subcooling in HVAC

Subcooling refers to the process of lowering the temperature of the refrigerant liquid below its saturation point to keep it in a purely liquid state. Subcooling ensures that the refrigerant remains entirely in liquid form as it exits the condenser unit.

The importance of subcooling lies in its direct impact on new system efficiency. When the refrigerant leaves the condenser as a subcooled liquid, it ensures that the liquid refrigerant is ready to absorb heat efficiently in the evaporator coil. This promotes superior cooling and dehumidification while optimizing the overall performance of the HVAC system.

Ensuring Proper Subcooling

Your HVAC system will operate at peak performance with the right maintenance and servicing.

Guidance on Checking and Maintaining Subcooling Levels

To measure subcooling, you’ll need a digital thermometer, a pressure gauge, and access to the manufacturer’s subcooling specifications for your HVAC system.

First, measure the temperature of the liquid refrigerant in the liquid line, close to the condenser unit. Make sure the reading is accurate.

Next, read the pressure.

Finally, calculate the subcooling. Cross-reference the pressure reading with the manufacturer’s specifications to determine the corresponding saturation temperature. Subtract this saturation temperature from the actual liquid line temperature to calculate the subcooling level.

Benefits of Maintaining Proper Subcooling Levels

By keeping subcooling at the appropriate levels, you can help ensure the efficiency of your HVAC system and prolong its operational life.

Maintaining the correct subcooling level guarantees that the refrigerant remains in liquid form, ready to absorb heat efficiently in the evaporator. This leads to optimal cooling performance and energy efficiency.

In addition, proper subcooling helps prevent issues like compressor damage and reduced system lifespan. The refrigerant circulates in its liquid state and reduces wear and tear on critical components.

Finally, maintaining the right subcooling levels facilitates a consistent and comfortable indoor environment, with no temperature fluctuations or humidity-related problems.

Troubleshooting with Superheat and Subcooling

The most common problems that may arise with superheat and subcooling are having a low superheat, a high subcooling, or pressure discrepancies:

Low Superheat

If superheat levels are lower than expected, you may have an issue with the refrigerant charge. Insufficient superheat could be due to overcharging, a malfunctioning metering device, or excessive air in the evaporator coils. If you measure superheat, you can pinpoint the root cause and rectify the problem for optimal system performance.

High Subcooling

When subcooling levels are higher than the manufacturer’s specifications, it may suggest an overcharge of refrigerant or an issue with the condenser. This information can lead you to adjust the refrigerant charge or inspect the condenser to bring subcooling back to the desired range.

Pressure Discrepancies

A disparity between the pressure measurements and saturation temperatures may signal potential problems with the expansion valve or clogged filters. Superheat and subcooling data can help you pinpoint these issues quickly.

Why Accurate Superheat Measurement Matters

When the superheat is too high, the system does not cool properly and uses more energy than it should. This means your home may feel warm, and your energy bills may go up.

When the superheat is too low, liquid refrigerant might reach the compressor. This can cause serious damage because the compressor is designed to handle only gas, not liquid.

By measuring superheat, we can check if the system has the correct amount of refrigerant and make sure all parts are working properly. This helps keep your HVAC system safe, efficient, and long-lasting.

Common Causes of Superheat and Subcooling Imbalance

Common reasons for superheating and subcooling include issues such as liquid line restriction, malfunctioning metering systems, and limited airflow, all of which can lead to high superheating and low subcooling levels.

1. Liquid Line Restriction.

Liquid line restrictions can occur due to clogged or dirty filter driers, kinks or bends in the line, or debris in the refrigerant line. It can lead to inadequate refrigerant flow, causing high superheat and low subcooling. As a result, the evaporator may not receive enough refrigerant, leading to reduced cooling capacity and potential icing of the evaporator coils.

2. Malfunctioning Metering Systems.

Metering devices like expansion valves and capillary tubes can malfunction due to wear and tear, dirt buildup, or corrosion. When the metering system malfunctions, it may allow an excessive amount of refrigerant into the evaporator, leading to low superheat. On the other hand, it may restrict refrigerant flow to the condenser, causing high subcooling. Both scenarios result in inefficient system operation.

3. Excessive Air in the Evaporator Coils.

Air can find its way into the evaporator coil due to refrigerant leaks, improper installation, or inadequate maintenance. Air in the evaporator can interfere with heat transfer, leading to low superheat. It causes the refrigerant to evaporate prematurely, reducing cooling efficiency. At the same time, it can increase the pressure in the condenser, contributing to high subcooling.

4. Limited Airflow in the Evaporator.

Limited airflow can result from clogged air filters, blocked vents, or issues with the blower motor. Reduced airflow can lead to reduced heat exchange in the evaporator coil, causing low superheat. It may also cause the evaporator to freeze due to insufficient warm air passing over the coil. Additionally, the limited airflow can impact the condenser, raising subcooling levels.

Superheat vs. Subcooling: Key Differences Every HVAC Owner Should Know

Superheat and subcooling are two important measurements that help HVAC technicians understand if your system is working correctly. Both are about checking the temperature of the refrigerant at different stages, but they serve different purposes.

Superheat is the amount of heat added to the refrigerant gas after it has fully changed from liquid to vapor in the evaporator coil. It is measured on the suction side of the system. Superheat helps make sure that only vapor reaches the compressor, because liquid refrigerant can damage it.

Subcooling is the process of cooling the refrigerant liquid below its boiling point after it has left the condenser coil. It is measured on the liquid side of the system. Subcooling makes sure that the refrigerant is fully liquid before it enters the expansion valve, which helps your system cool your home properly.

The key difference is that superheat protects the compressor by ensuring the refrigerant is in gas form, while subcooling ensures efficient cooling by making sure the refrigerant is in liquid form. At Pure Eco Inc., our technicians always check both superheat and subcooling. This helps us find problems early, adjust refrigerant levels correctly, and keep your HVAC system running safely and efficiently.

Pure Eco Inc. Can Help

It’s helpful to know how your HVAC system works and how to keep superheat and subcooling in balance. However, you may not wish to maintain your HVAC system yourself and prefer to hire Pure Eco Inc. HVAC technicians to give you a comfortable and consistent indoor climate.

For example, a client in Los Angeles contacted us because their AC wasn’t cooling well, and their energy bills were rising. Our technician discovered that the superheat was too high at 28°F. After carefully adjusting the system, we brought it down to 14°F, which improved cooling and led to a 15% drop in energy use the following month.

As our Senior Technician, Eli explained, “Fixing superheat made the system run smoother and use less energy. A small adjustment saved this client money and improved comfort.”

Take control of your indoor air quality with Pure Eco Inc.‘s expert HVAC services. We are committed to excellence and make sure your system runs at top performance.

Contact us now at 1-877-870-7998 because your comfort is our top priority, and you deserve the best.

Measuring superheat and subcooling is essential in HVAC maintenance because it confirms the system is properly charged and operating efficiently. Incorrect levels can cause issues like poor cooling, higher energy bills, system strain, or even compressor damage. Homeowners can help keep their system efficient by changing filters, keeping outdoor units clear, sealing air leaks, using smart thermostat settings, and scheduling yearly maintenance. Regular tune-ups are especially important, as technicians check superheat and subcooling levels to catch problems early, preventing costly repairs and extending the life of the system.

Eli, Senior Technician at Pure Eco Inc.

FAQ

What is superheat in HVAC?

Superheat is the extra heat added to the refrigerant gas after it boils. It shows the refrigerant is fully vapor and protects the compressor from damage.

What is subcooling in HVAC?

Subcooling is when the refrigerant liquid is cooled below its boiling point. This helps your system cool better and work efficiently.

How do I calculate superheat?

Measure the temperature of the suction line (T1) and the pressure (P1). Convert P1 to saturation temperature (T2). Superheat = T1 – T2.

What does high superheat and low subcooling mean?

This usually means there is not enough refrigerant in the system. The evaporator isn’t getting enough refrigerant to cool properly.

Can low airflow affect superheat and subcooling?

Yes. Low airflow can cause low superheat and low subcooling because the system can’t absorb enough heat.

How often should I check superheat and subcooling?

During every HVAC maintenance visit, or if you notice poor cooling or high energy bills.

Can I adjust superheat myself?

No. It needs special tools and training. It’s best to call a licensed HVAC technician.

Why are superheat and subcooling important?

They help your system cool well, save energy, and protect expensive parts like the compressor.

Sources

https://www.buildingengines.com/blog/knowledge-superheat-and-subcooling/

https://www.reddit.com/r/HVAC/comments/f8bcv2/superheat_and_subcooling_explained_hvac_101/

https://www.reddit.com/r/HVAC/comments/14aj5co/beginner_here_im_trying_to_understand_superheat/

https://www.rsi.edu/blog/hvacr/what-is-superheat-in-hvac/

https://en.wikipedia.org/wiki/Subcooling

https://www.achrnews.com/articles/94178-superheat-and-subcooling-made-simple