Key Takeaway

- Wet insulation is never just damp material. It’s a chain reaction that undermines comfort, safety, and efficiency.

- The moment water displaces insulation’s air pockets, you lose R-value, get higher energy bills, and hidden mold begins to grow.

- Health risks climb as spores, dust mites, and bacteria spread into the living space, while structural damage threatens ceilings, walls, and roof decking.

- Some materials, like cellulose and open-cell spray foam, can never be salvaged, while fiberglass and mineral wool only survive if dried within 24 hours.

- The smartest path forward isn’t guesswork: it’s a professional inspection, clear remediation plan, and long-term prevention strategy

- With Pure Eco Inc. services, you get lasting protection for your home, lower energy costs, and healthier indoor air for your family.

Why Wet Insulation Matters More Than You Think

Insulation works by trapping dry air in tiny pockets that slow heat transfer. When water fills those spaces, insulation loses its R-value, collapses under weight, and stops doing its job. That means problems that escalate quickly if left untreated:

- Your energy bills dramatically increase because the HVAC unit runs longer to compensate.

- Comfort drops: rooms located under wet attics feel drafty in winter and stifling in summer.

- Health risks rise: moisture fuels mold spores, dust mites, and bacteria.

- Structural safety is at stake: wet insulation can warp roof sheathing, rust fasteners, and collapse ceilings.

The U.S. Department of Energy confirms: “Moisture is the single greatest threat to building durability.”¹

What Happens When Insulation Gets Wet (By Material)

Each insulation type responds differently to water. Some can be salvaged if caught early, while others must be replaced immediately to avoid long-term damage.

Fiberglass batts

Fiberglass batts tend to clump when they get wet, reducing loft and lowering their R-value. If left damp, fiberglass bats can lead to mold growth, too. In some cases, fiberglass batts can be salvaged if they are dried within 24 hours and show no signs of odor, mold or mildew.

Blown-in fiberglass

Blown-in fiberglass settles into a dense mat when it absorbs water. This compression permanently reduces its insulating ability, making it very difficult to restore performance. In most cases, blown-in fiberglass must be replaced after water damage.

Cellulose

Cellulose insulation is made from recycled paper products, so it acts like a sponge when exposed to water. Once wet, it absorbs and holds moisture, quickly developing mold and becoming extremely heavy. Because cellulose never regains its original insulating properties, it must always be replaced after water damage.

Open-cell spray foam

Open-cell spray foam has a soft, sponge-like structure that easily absorbs water. Once saturated, it traps moisture inside its cells and creates long-term mold risks and structural issues. For this reason, open-cell spray foam cannot be salvaged and should be replaced if it gets wet.

Closed-cell spray foam

Closed-cell spray foam is much more resistant to water. Its dense, rigid structure can keep water from penetrating, helping it maintain both its shape and insulating ability even after exposure. In most cases, closed-cell spray foam remains unharmed and can stay in place once the leak source is fixed.

Mineral wool

Mineral wool is naturally hydrophobic. This means it resists absorbing water. If it becomes damp, it often dries out without losing its shape or R-value. With proper drying and ventilation, mineral wool insulation can usually be salvaged after minor water exposure.

Expert insight by Beni, Senior Technician at Pure Eco Inc.: “Cellulose is unrecoverable once wet. It grows mold in days and collapses. With fiberglass, timing is everything. Catch it early, and sometimes you can save sections.”

Wet Insulation in Attic vs. Wet Insulation in Ceiling

- Attic insulation: Usually soaked from roof leaks, ice dams, or condensation. When attics are poorly ventilated, moisture lingers and spreads mold across joists and roof decking.

- Ceiling insulation: Often damaged by pipe leaks or overflowing HVAC pans. Wet insulation can become hazardously heavy above drywall, which is enough to collapse ceilings if not removed as soon as possible.

That’s why thermal imaging and moisture meters are part of every Pure Eco inspection. What looks “dry” to the eye often hides dangerous dampness.

Drying vs. Replacing: A Homeowner’s Decision Matrix

Timing, contamination level, and insulation type decide whether you can dry or must replace.

|

Condition |

Fiberglass Batt |

Blown Fiberglass |

Cellulose |

Open-Cell Foam |

Closed-Cell Foam |

Mineral Wool |

|

Clean leak, <24h wet |

Dry & reinstall |

Replace if settled |

Replace |

Replace |

Inspect/Dry |

Dry |

|

Gray water, >24h |

Replace |

Replace |

Replace |

Replace |

Replace |

Replace |

|

Visible mold/odor |

Replace |

Replace |

Replace |

Replace |

Replace |

Replace |

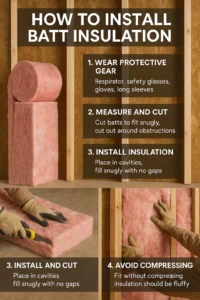

Step-by-Step: How to Dry Out Insulation

If you discover wet insulation, you need to move fast. You see, mold colonies can begin developing within 24–48 hours.

- Stop the leak. Call a professional crew to have your roof, pipe, or HVAC overflow repaired.

- Ventilate & dehumidify. You can open soffit/ridge vents, run attic fans, and use a dehumidifier.

- Remove damp sections. How? Batts can be pulled out and dried in direct sunlight; blown-in insulation usually clumps and requires replacement.

- Inspect for mold. Signs such as odors, spots, or discoloration entail replacement.

- Restore code-level R-value. To meet R-value standards, you need to replace or reinstall insulation.

Important safety note: Do not sweep or vacuum wet cellulose. Disturbing it can release bacteria and spores into the air.²

Cost Analysis: Drying vs. Full Remediation

When insulation gets wet, homeowners often look for the cheapest path forward. However, the real costs depend on how quickly the damage is addressed, the insulation type, and the level of contamination.

Drying & salvage (low cost option)

If fiberglass batts or mineral wool are caught within the first 24 hours after a clean water leak, drying may be possible. This approach usually involves:

- Removing damp batts

- Drying them in a well-ventilated area

- Reinstalling once moisture levels drop

However, if moisture lingers longer than a day, or if the water source was contaminated (such as gray water from a pipe), salvage is no longer safe or effective.

Partial replacement & sanitation ($1.50–$2.50 per sq. ft.).

In cases where part of the insulation can be saved, homeowners may choose a partial replacement strategy. Technicians work to:

- Remove saturated sections

- Disinfect the surrounding framing to kill bacteria/spores

- Install fresh insulation where needed

It’s a smart balance for small leaks, but not ideal if the entire attic or ceiling is exposed to heavy moisture.

Full remediation ($2.70–$4.50 per sq. ft.)

When large sections of insulation are saturated, mold is detected, or the leak goes unnoticed for days, full remediation is the only long-term solution. This process entails:

- Complete removal of wet/contaminated insulation

- Sanitation and deodorization

- Air sealing to prevent condensation

- Installing new insulation to code-level R-values

This approach, although it carries the highest upfront cost, delivers the most value because it improves energy efficiency, restores indoor air quality, and eliminates the risk of repeat infestations or mold growth.

The bottom line: While drying looks like the cheapest path, it’s a narrow window that rarely applies outside of very minor leaks. For most homes, partial replacement or full remediation is the safer investment, especially if health, energy efficiency, and property value are priorities.

Long-Term Prevention: How to Keep Insulation Dry

At Pure Eco Inc., we believe remediation is only half the battle. The real goal is prevention, as you need to make sure wet insulation never becomes a recurring problem. Moisture control in attics, walls, floors, and ceilings requires a multi-layered approach that combines building science with routine care.

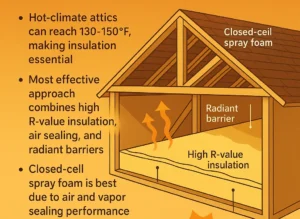

Air sealing

One of the most common causes of wet insulation is warm, humid air escaping from the living space below and condensing in the attic. Pure Eco Inc. specializes in sealing these gaps with durable, weather-resistant materials. Proper air sealing only prevents condensation and boosts energy efficiency by stopping wasted airflow.

Balanced ventilation

Proper ventilation isn’t only an attic concern. Every part of your home needs to “breathe.” When airflow is blocked in walls, floors, or ceilings, moisture builds up and eventually seeps into insulation, drywall, and wood framing. This trapped humidity creates the perfect conditions for mold inside walls, mildew beneath floors, and rot in structural beams.

Pure Eco Inc. evaluates the entire home for airflow issues to correct them, protecting your home year-round against hidden mold growth, indoor air quality problems, and costly structural repairs.

Durable materials

Some insulation types are more vulnerable than others.

- Cellulose and open-cell spray foam absorb water easily and seldom recover once saturated.

- Closed-cell spray foam is both an insulator and a vapor barrier, making it highly resistant to moisture damage.

- Mineral wool is naturally hydrophobic, resisting water absorption and drying quickly after minor exposure.

Upgrading to closed-cell spray foam or mineral wool dramatically lowers long-term risk in homes prone to leaks or high humidity.

Annual inspections

The final piece of prevention is vigilance. Even with air sealing and ventilation in place, small roof leaks, flashing failures, or plumbing issues can go unnoticed. Early intervention prevents costly replacements and keeps your home healthy, safe, and energy efficient. That’s why we recommend annual attic inspections, especially after heavy storms.

“Most families don’t call until energy bills rise or odors spread,” says Beni. “By then, it’s already a full-blown remediation job. A quick annual inspection could save thousands.”

Protect Your Home & Health

Wet insulation is a warning sign that your home’s comfort, safety, and efficiency are at risk. Acting quickly can mean the difference between a minor repair and a costly remediation. At Pure Eco Inc., we can restore your attic to a clean, energy-efficient, and protected space while putting safeguards in place to keep moisture from coming back. If you suspect your insulation has been exposed to water, call Pure Eco Inc. for a free moisture and insulation check.

Frequently Asked Questions

What happens when insulation gets wet?

It loses R-value, collapses, and can harbor mold. Fiberglass and mineral wool may dry if caught early, but cellulose and open-cell foam need to be replaced.

How do I know if insulation is wet?

Signs may include musty odors, ceiling sagging, discolored drywall, or higher humidity. Professional thermal scans detect hidden dampness.

Can wet insulation dry on its own?

Rarely. Without forced ventilation, water remains trapped. Active drying or replacement is needed.